EFT provides the technology to transition to sustainable and lower-carbon fuels.

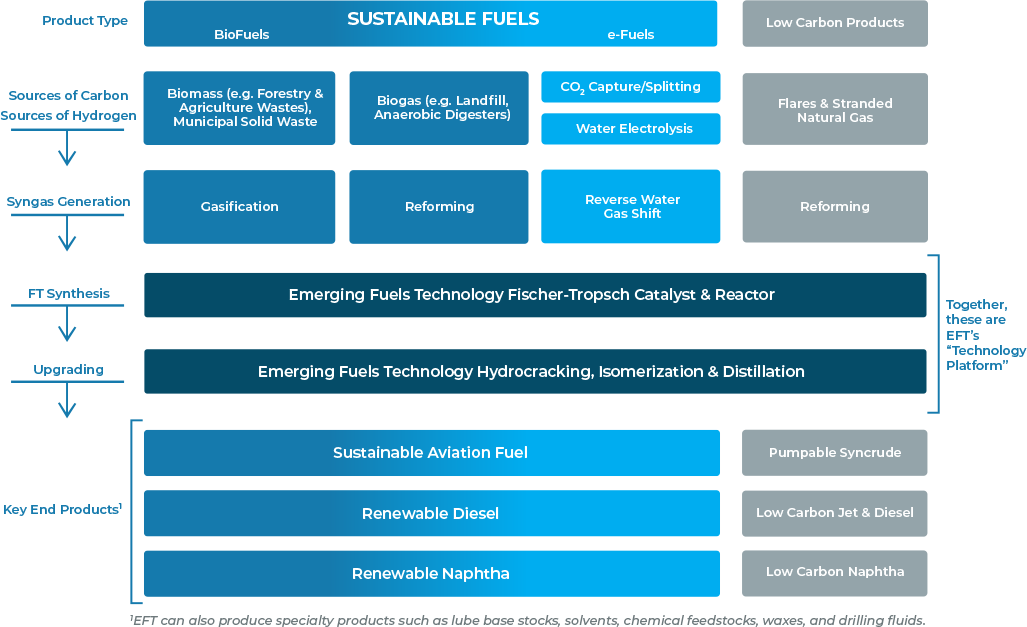

EFT's Fischer-Tropsch catalyst and reactor system plus our upgrading technology is a proven high-yield solution for project developers seeking to make sustainable fuels from biogas, biomass or CO2. The same technology can be applied to eliminate flares and convert stranded natural gas to lower-carbon fuels.

We partner with licensees worldwide at every stage of project development, delivering customized FT synthesis and upgrading solutions that maximize fuel production, cost-efficiency, and scalability.

Process Engineering & Feasibility Support

Demonstration Plants

Process Design Package

Demonstration Plants

EFT’s flexible technology platform can be applied across a range of feedstocks to produce high value products.

Contact us to discuss your project and learn how EFT’s cutting-edge FT technology can support your sustainable fuel production goals.

Get in Touch

Cutting-edge R&D, testing, and process development to accelerate fuel innovation.

EFT operates a state-of-the-art catalyst and process development facility in Tulsa, Oklahoma, designed to support the advancement of sustainable and lower-carbon fuels.

Our fully operational, 24/7 research facility provides pilot plant, process integration, and engineering support, offering:

EFT Development Facility, Tulsa, Oklahoma

Process Integration

Developing processes to integrate syngas technologies with our Fischer-Tropsch synthesis and upgrading technology.

Demonstration Plants

To demonstrate a fully-integrated system for fuel production.

EFT’s expertise and cutting-edge facility can support your development goals.

Get in Touch

A scalable, modular, and cost-effective solution for converting renewable biogas into drop-in transportation fuels.

Biogas is a vast, scalable, and underutilized resource that can be converted into sustainable aviation fuel (SAF), renewable diesel, and gasoline blendstock (naphtha) using EFT’s Biogas-to-Liquids (BioGTL) technology.

EFT’s BioGTL plant is an ideal solution for landfills, agricultural bio-digesters, and wastewater treatment facilities. With a low CAPEX per unit capacity, BioGTL provides the lowest-cost SAF production pathway available today.

Plot area required – less than 100 ft x 120 ft

Generates most of its own power

Requires no water source

Will run unattended with remote (satellite) monitoring equipment included

Built entirely from truckable modules

Can be disassembled and moved relatively easily

Product storage is included in cost estimate

Engineered for small-scale economic viability—not just a scaled-down version of large plants.

Avoids costly mismatches between technologies by optimizing the entire process chain.

EFT’s technology presently produces over 80% Jet or Diesel and under 20% Naphtha with development underway to offer 100% Jet or Diesel.

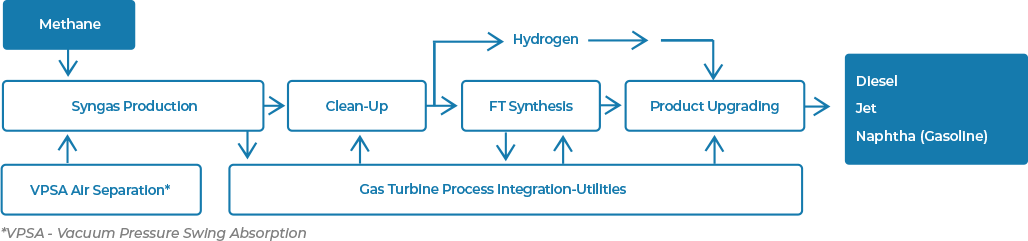

A scalable, low-cost solution for methane mitigation and resource recovery.

Methane is 25 to 28 times more potent than CO2 as a greenhouse gas. Vented and flared methane is one of the largest contributors to global emissions, wasting valuable resources.

Flarebuster™ provides an efficient, modular solution to convert stranded and flared gas into valuable liquid fuels—helping reduce emissions while producing commercial products such as jet fuel, diesel, naphtha, and more.

With a fully patented design, mature technologies, and low CAPEX per barrel, Flarebuster enables cost-effective deployment, including at remote locations without external power.

With a fully patented design, mature technologies, and low CAPEX per barrel, Flarebuster enables cost-effective deployment, including at remote locations without external power.

EFT is committed to commercial deployment of Flarebuster™, driving industry-wide adoption of methane mitigation technologies.

Contact us to learn more.